You can see that desiccated coconut in all forms is in hype today in the modern health and wellness world. You might have seen coconut shavings wrapped in plastic bags in the supermarket. They have high nutritional value and come with other benefits too.

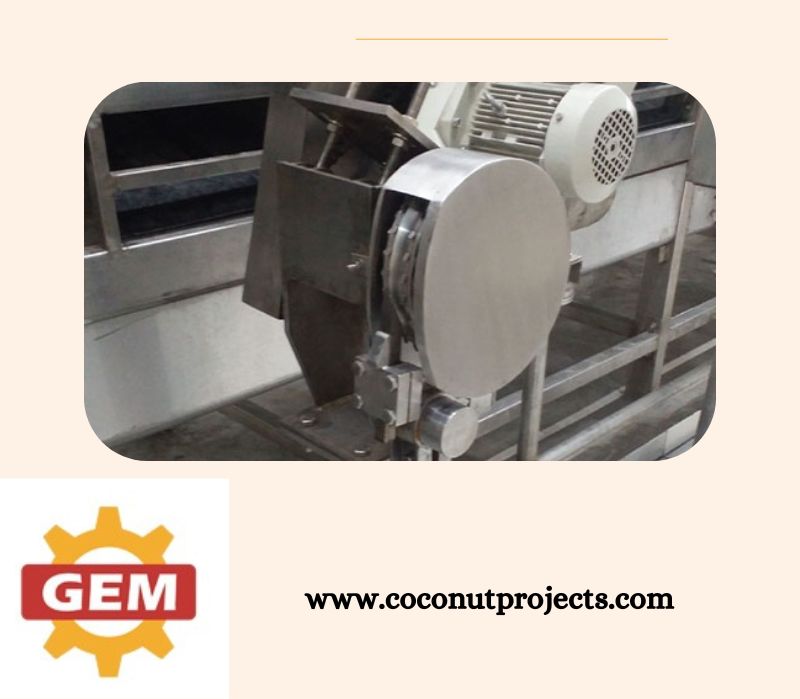

Yes, with the desiccated coconut, you can do it all. Large-scale producers can easily bring out the desiccated coconut in large amounts using the best quality coconut paring oil machine.

In this blog, you can learn about the details of desiccated coconut and its various uses.

Defining And Understanding Desiccated Coconut

Desiccated coconut is also called shredded coconut. It refers to the drying out and removing all moisture from it. It is the dried and granulated form of coconut.

This desiccated coconut is made by thinly slicing mature white flesh and then drying it in hot air at 100 degrees centigrade. It has a good flavour and is dry to the touch. Though the finely grated dehydrated coconut is the most common, it is also available in shredded, chipped and granule forms.

This chopped coconut is used in sweets, baked items and cereals in different parts of the world. However, nowadays, the granulated form of coconut is put in diets to gain health benefits.

Granulated Coconut- A Highly Nutritive Value Food

Yes, this coarse coconut is very helpful for health when included into your diet and active lifestyle. It also improves the flavour of food and beverages and contains vitamins and minerals that are good for your overall health.

Though coconut is rich in fat, it also has nutrients. It is considered a fruit as well as a nut. It is not to consume a whole coconut daily; adding some portions of desiccated coconut as a texture to a balanced meal makes good sense.

Instead of using artificial sweeteners, you can try sprinkling desiccated coconut. This way, you can enjoy delicious food without extra calories and sugar.

Wrapping Up

If there is a fruit you like to live on, be it the coconut. With its huge abundance in the market and nutritional value, you can always go right with serving a desiccated coconut a day. Desiccated coconut suppliers make huge amounts of grated coconut and other by-products with different coconut paring oil machinery.

The machines include Hammer Mill, coconut paring dryer, oil expeller, filter press, etc. Buy latest coconut paring oil machines from Gem allied Industries Private Limited. Check our website now.