Coconut Biodiesel Processing Plant

Looking for an eco-friendly, high-efficiency solution to produce biodiesel?

Our Coconut Biodiesel Processing Plant is engineered to convert refined coconut oil (RBD) into high-quality biodiesel fuel using the proven transesterification process. Ideal for regions rich in coconut resources, this system supports clean energy production, rural development, and sustainable industries.

Why Choose Coconut Biodiesel?

- 100% Renewable: Made from coconut oil, a sustainable natural resource.

- Low Emissions: Produces significantly less CO₂ and sulfur than petroleum diesel.

- Biodegradable & Non-Toxic: Safe for the environment and fuel handling.

- Superior Fuel Quality: High cetane number (65–70) and excellent combustion performance.

- Supports Local Economies: Creates value from coconut farming and agro-industrial waste.

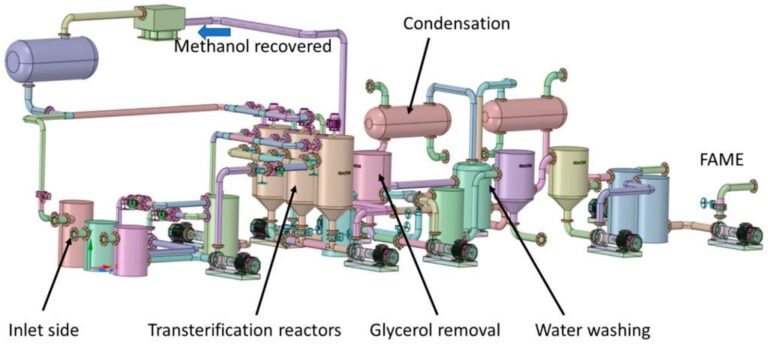

Plant Features & Technology Our biodiesel production system includes:

- Pre-treatment Units – Removes impurities and adjusts FFA levels

- Reactor System – Transesterification at 50–60°C using a 6:1 methanol-to-oil ratio

- Glycerin Separation – Settling tanks or centrifuge technology

- Water Washing & Drying – Purifies the final biodiesel

- Final Filtration & Storage Tanks

Technical Specifications: | |

| Specification | Feedstock |

| Biodiesel Yield Up to 98% | RBD Coconut Oil |

| KOH or NaOH (0.5–1% by weight) | Catalyst |

| Feature | |

| Viscosity | 2–4.5 mm²/s @ 40°C |

| Moisture Content | <0.05% |

| Compliance Standards | ASTM D6751 / EN 14214 |

All plants are customizable and can be designed for manual, semi-automatic, or fully automatic operations.

- Applications of Coconut Biodiesel

Automotive fuel for diesel engines

Power generation in diesel generators

Sustainable transportation and logistics

Industrial machinery and marine engines

Invest in Clean Energy. With increasing global demand for biofuels, investing in a coconut biodiesel plant offers long-term profitability, environmental impact, and energy security.

Ready to start your biodiesel production journey?

Contact us for: Feasibility studies

- Custom plant design

- Cost analysis & ROI reports

- Installation & technical support